vario pro

vario pro user information

On this page you will find all the information you need to use the vario pro system easily and without problems.

If you want to jump directly to a topic, use the side menu or the corresponding direct links.

The following pdf files are available here for you to print out:

Brochure vario pro dosing unit

Dosage instructions

Pick-up switch installation instructions

System overview

System overview

Cooling tank

The insulated tank with fill level display protects the bacteria from heat. It holds 20 litres and its lid is secured with expander loops. It is attached to the machine individually in the frame.

The mixing ball ensures a permanent mixing process in the tank due to the constant movement of the machine. The vario cool box with the cool pack is used to keep the silage bags cool during transport. The cool pack can also be placed in the tank at warm temperatures. A whisk and dosing plan complete the set.

Weatherproof stainless steel socle

Robust holder for the cooling tank, the pump and an additional 10 A fuse. It can be mounted variably on the machine.

The sturdy suction strainer prevents foreign particles from entering the mechanics.

At least 2.5 metres hose length

There must be 2.5 metres of hose between the diaphragm pump and the non-return valve to ensure smooth operation.

Holder and flow meter (2 - 40 l)

The holder with the flow meter should be assembled vertically, preferably within the machine operator’s sight area. It makes easy to remove the flow meter and holds it securely in place.

2 Nozzle holders (nozzle set included)

One or both can be connected as required. This makes it suitable for many different appliances. The hose length can be customised. Nozzles:

- brass (2 - 8 l/h)

- orange (8 - 20 l/h)

- green (20 - 40 l/h)

12-Volt diaphragm pump

The pump is integrated in the frame. It has a pressure switch and switches off in the event of overpressure to prevent damage.

In the event of an overload or short circuit, a 10 A fuse protects the appliance and the lines. It can be easily replaced by unscrewing the plastic cover.

Cleaning & disinfection

All components and pipes should be thoroughly cleaned with water and, if necessary, disinfected after each use to remove silage additive residues and prevent the formation of a biofilm.

To prevent damage to the device, it should not be stored for long periods with disinfectant solution in it.

After disinfection, rinse the appliance including all components twice with clear water.

vario pro and attachments must be completely emptied after the season and stored frost-free to prevent frost damage.

Dosage

Calculation of the flow rate / examples

- Determine/estimate silage output (t/h) (example: 25 t/h)

- Determine quantity of silage additive mixed (ml/t) (example: 150 ml/t) (example calculation flow rate: 25 t/h x 150 ml = 3.75 l/h)

- Select suitable nozzles, set the mark on the flow meter (example: 3.75 l)

- Check: run appliance with water for 20 min, collect water (example: [3.75 l / 60 min = 0.0625 l/min] x 20 min = 1.25 l water in the bucket)

- Estimate the tonnage to be treated (example: 400 t) and calculate the required silage additive solution: (example: 400 t x 150 ml/t = 60 l silage additive solution) (The tank holds 20 l, so a total of 3 tank fillings are required.)

Nozzle selection

| Nozzle color | Number | Quantity range l/h (water solution) |

Remark | |

|---|---|---|---|---|

| from ... | to ... | |||

| Brass | 65050 | 2 | 8 | with 2 nozzles |

| Orange | 11001 | 8 | 20 | with 2 nozzles |

| Green | 110015 | 20 | 40 | with 2 nozzles |

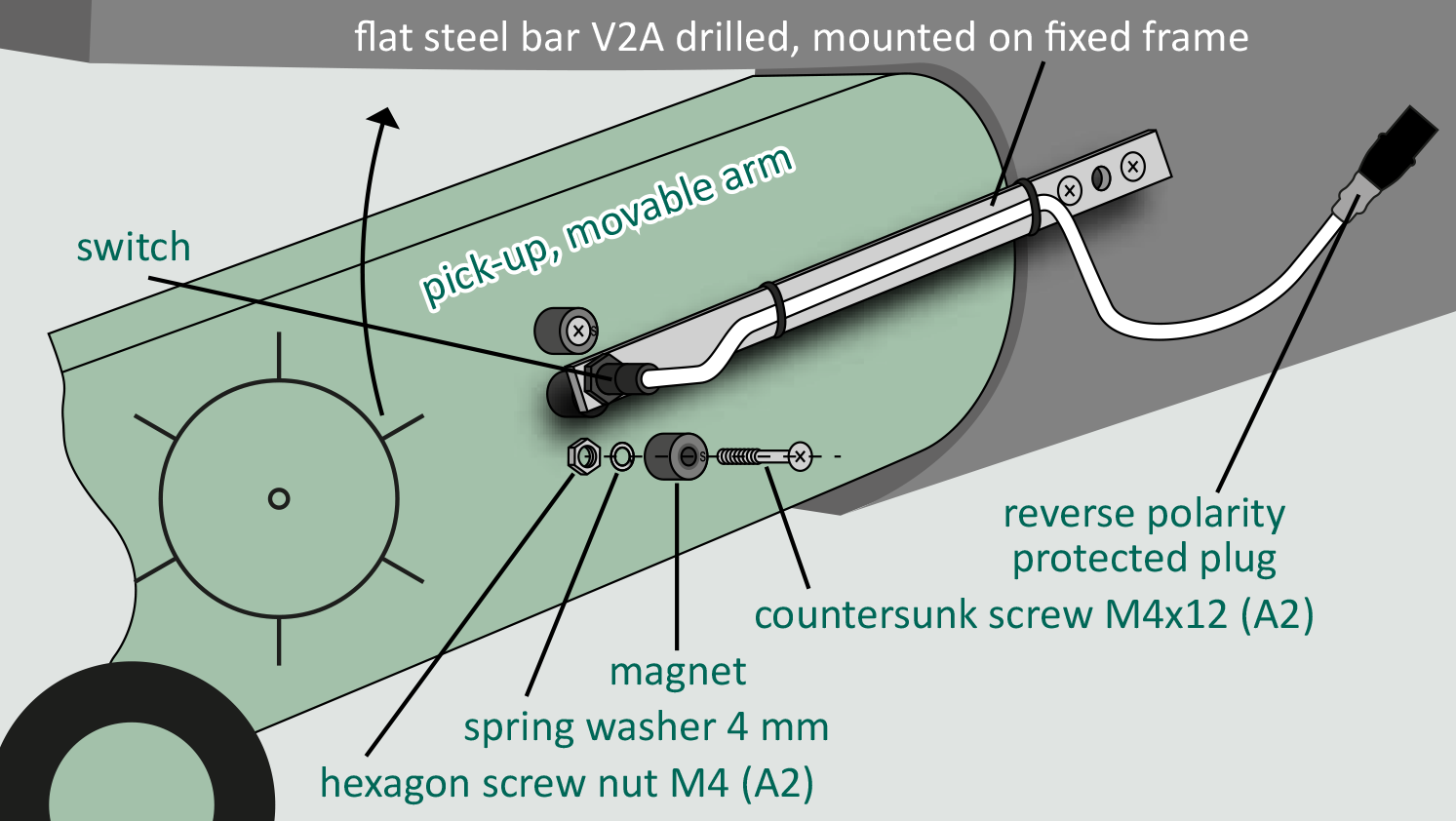

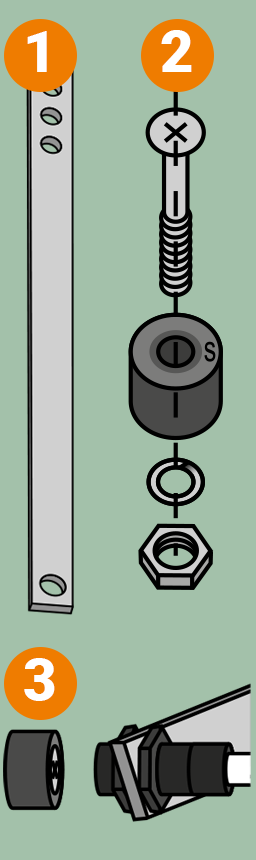

Mounting the pick-up switch

Mounting example

ATTENTION: Installation like the example shown – but may vary in some points depending on the model and manufacturer!

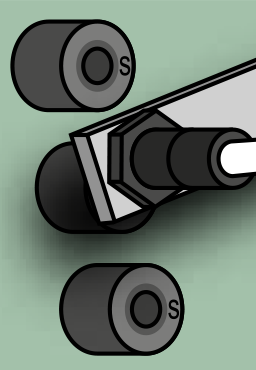

Transport position (switch :off):

Place the switch in the flat steel bar. Fasten the flat steel bar (e. g. initially using a screw clamp) to the stationary frame so that the magnetic switch is close to the lower edge of the movable pick-up arm. ATTENTION: The temporary attachment must be at least 1.5 cm away from the center of gravity of the flat steel bar! Now attach the bottom magnet to the movable pick-up arm, approx. 3 - 4 cm above the switch, and the other two magnets above it at a small distance.

Working position (switch on):

Check whether the switch is at the same height as the magnets, readjust if necessary. If the switch is in the area of the magnets in the working position and clearly outside in the transport position (test the switch function if necessary), mark the positions of the switch and magnets.

Mounting:

1 Screw or weld on the flat steel bar (welding WITHOUT the switch inserted!).

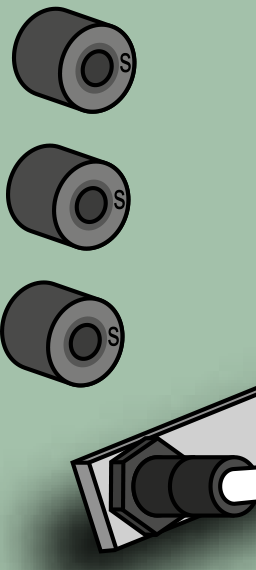

2 Attach the magnets using the countersunk screws supplied. ATTENTION: The south pole of the magnets (S) MUST be visible!

3 Readjust the distance between the switch and the magnets – there should be a gap of 1 - 2 cm between the front of the switch and the magnets. Tighten the screw nuts moderately. Notes: Only for load voltage 12 or 14 V DC up to 6 W, protection rating IP 65.

faq

The spray pattern of the nozzles is strange / it only drips

How is the flow rate set?

The nozzle specifications are the minimum and maximum - not the optimum. Of course, the spray pattern is different if I have a lower flow rate: At 2 l/h, significantly less liquid runs through the nozzle than at 10 l/h - similar to the jet on a tap: the more the water is turned on, the ‘harder’ the jet is and at very little it just drips.

IMPORTANT: Bacteria do NOT have legs!

This means that they need moisture to spread. For this reason, the flow rate and therefore the water content can be increased, especially with dry material. The dosage must then be adjusted depending on the dissolution ratio of the silage additive.

The nozzles are constantly leaking

There could be air in the system. To solve this problem, please follow the steps below:

1. Fill the tank: Fill the tank completely with water.

2. Remove the nozzles: Deinstall the nozzles to allow an unhindered flow.

3. Take the air out of the pump: Run the pump at ‘high speed’ until no more air bubbles come out and only water flows.

Contact us

Contact information

If you have any further questions, simply get in touch with us. We will certainly find a solution together.

Adress

joachim behrens scheessel gmbh, Milchstraße 1, D-27374 Visselhövede, Germany

service@jbs-agrar.com

Phone

+49 4262 - 2074 0

Working hours

Monday - Friday, 7.30 a. m. - 4.30 p. m.